A comprehensive technical study has been carried out to define short- and medium-term action for the rehabilitation of the raw water catchment works and each of the unitary processes of the drinking water treatment plant in Las Pavas, El Salvador. This makes it possible to improve the conditions of collection, treatment and operation once the operative and physical diagnosis has been made. The production capacity of the plant is 3 m3/s, which serve to supply a population of 1.5 million inhabitants.

In particular, it has been developed:

-

Preliminary or site studies.

-

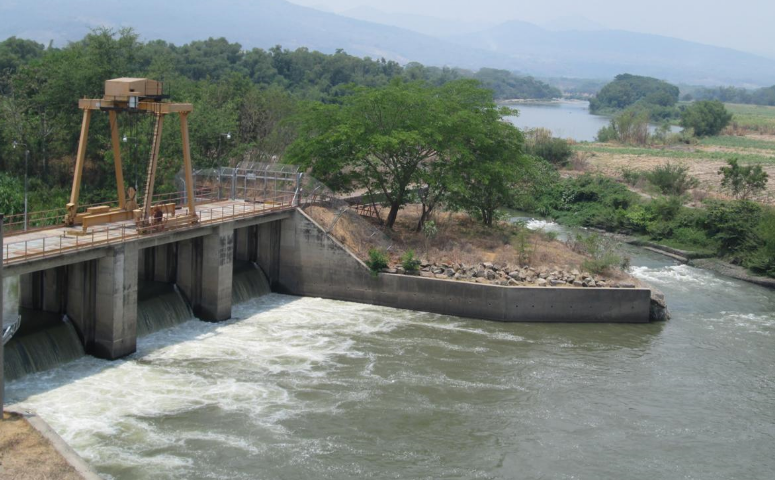

Activities in the Lempa River for the conditioning of the catchment area, among which the following stand out:

- Dredging works on the channel.

- Extension of the relief channel

- Protection of the left bank of the river with a wall of gavions.

- Overflow in the main channel by means of a mixed structure of gavions and reinforced concrete.

- Protection of the left stirrup of the bocatoma dam.

- Protection of the bottom of the bed with armor of gavions.

- Drainage works in the environment of the bocatoma.

-

Adaptation of the Bocatoma and EB1 pumping stations. The following actions are highlighted:

- Replacement of the pumping, valve and boiler equipment of Bocatoma and EB1.

- Electrical equipment and Automation of Bocatoma and EB1 (transformers, switchboards, wiring, etc).

- Civil and architectural works required for the adaptation of the facilities.

- Determination of the energy efficiency of existing and new major equipment.

-

Improvement of the processes of the Potable Water Treatment Plant of Las Pavas. The following actions are highlighted:

- Improvement of the elements of the potabilization process: Bocatoma – Pretreatment – Coagulation-Floculation – Lamellar settling – Sand filtration – Final disinfection – Chemical plant and Flocculated Sediment Plant.

- Tank for recirculation of washing water.

- Water regulation and storage tank of 200,000 m3.

• Electricity, Automation and Civil Works of the Water Treatment Plant.

• Diagnostic report of the pumping stations known as EB2 and EB3.

• Financial Feasibility Study.

• Environmental Management Programme (WMP).

• Upgrading of the so-called EB2 and EB3 pumping stations. The following actions are highlighted:

– Replacement of pumping, valve and boiler equipment of EB2 and EB3.

– Electrical equipment and Automation of EB2 and EB3 (transformers, switchboards, wiring, etc).

– Civil and architectural works required for the adaptation of the facilities.

– Determination of the energy efficiency of existing and new main equipment.

• Design of an Anti-Shock Damper Tank.

• Elaboration of the Terms of Reference for the construction of an Electromechanical Maintenance Workshop.